Research and Development

Our journey begins in the laboratory, the heart of Schmincke, where our dedicated research and development team is devoted to crafting the exceptional formulations that define our high-quality artists’ colours. This is where our traditional recipes are thoroughly cared for, while continuous testing of new products and raw materials ensures that we uphold and expand our exacting standards. The laboratory is also at the forefront of developing innovative colours that respond to market demands.

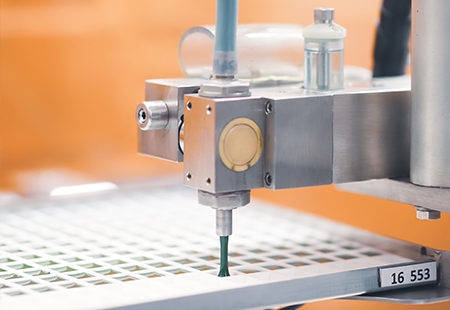

Quality Control

Integral to our entire production process quality control is a constant focus with the laboratory playing a pivotal role. Rigorous checks are conducted on freshly produced colours, ensuring they precisely adhere to the specified formulations before making their way to the consumer.

Raw Material Storage

Our extensive raw material storage accommodates over 300 pigments and all the necessary components for manufacturing colours and essential mediums.

Binder “Kitchen”

In this specialised area the solid, pasty and liquid substances used as binders for creating colours, painting mediums, varnishes and more are thoroughly prepared.

Weighing and Premixing

Our experienced staff is combining the formulations from the binder kitchen with the pigments in the weighing area. Each ingredient is precisely weighed according to specified formulations and the colours are skillfully premixed.

Grinding Room

The premixed colours are carefully ground in the grinding area. Using three-roll mills with tempered steel rollers rotating at different speeds, colours are finely ground based on the formulation and type.

Maturation (Oils)

Post-grinding our high-quality artists’ oil colours undergo a maturation process designed to optimise the absorption of oil and pigments. The duration of maturation varies based on the specific formulation. Excess oil is removed at the end of this period before the colours are carefully filled into tubes.

Filling Room I (Tubes and Bottles)

After grinding our high-quality artists’ colours rest in interim storage for a designated period. Afterwards they enter the filling room, where pasty colours are efficiently filled into tubes and labeled by advanced machines. Liquid colours are dispensed into bottles via a state-of-the-art filling line.

Filling Room II (Watercolor Pans)

Watercolour pans are filled using specialised machines utilising the established Schmincke patent. This intricate process occurs in four phases. After each filling layer the pans enter drying chambers, undergoing an 8 to 14 day drying period under constant climate conditions. Following a thorough final inspection, the pans are machine-packaged with film and label.

Production of Pastels

Snail rollers expertly shape pre-kneaded colour dough into round strands, which are hand-cut into suitable lengths on a wire mesh frame. The still-moist sticks then undergo an approximately 8-day drying period. The labeling of our extra-soft pastel sticks is a manual process, reflecting the artisanal care that goes into each creation.