Lightfastness – A Measure of the Durability of Artists’ Colours

Product InformationAny artist who is concerned about the longevity of her works will put a premium on the lightfastness of her paints. Light has a dramatic impact on works of art: both in a positive sense, in terms of the effect of colour, and in a negative sense, in terms of their dura- bility – unless highly lightfast artists’ colours are used.

Everyone has seen the negative effects of light on low-lightfast colours, especially in bright fabric or printed material. As these products are not designed to last for a long time, the intensity of their colours degrades significantly in a short time. Direct sunlight is the biggest culprit in causing colours to fade. Light also degrades materials – wood and plastics become brittle, while newspaper turns yellow.

Works of art, on the other hand, are supposed to be longlived, with colours whose brilliance and luminosity remain unimpaired after years or even decades. We at Schmincke have always stressed the importance of quality, including the lightfastness of our artists’ colours.

While all the components in an artists’ colour – pigments, binders and special additives – determine how lightfast the dry layer of paint will be, lightfastness depends mainly on the kind of pigment in the colour. The durability of a particular hue is not an accidental property. There are many ways to produce the pigment and many different components that can be used in the artists’ colour (formula). Which of these options are selected greatly determines the final result of the production process. The ability to develop the “right” formula that also meets all the key requirements for an artists’ colour is an essential piece of “know-how” in the production of artists’ colours. It is, in essence, the secret behind highquality artists’ colours and maximum lightfastness.

At Schmincke, we place the utmost importance on specifically optimizing formulas to maximise lightfastness and on maintaining our current quality standards. That requires using an objective testing procedure. One such procedure, a “lightfastness test”, is as follows: The lightfastness tests are always run on the finished Schmincke colours, not on individual components of the formula. This is important for the simple fact that even those paints with extremely lightfast pigments may change colour if the wrong binders or additives were used. Thus, we don’t merely check how the pig- ment changes (colour fading), but can instead see the entire gamut of changes to the colour (darkening, changes in lustre, etc.).

Here’s an example: In and of itself, the pigment titanium white is extremely lightfast. Once mixed in an oil colour based on pure linseed oil, however, it will eventually darken from its initial titanium white. This earns it a poorer lightfastness rating, and is one of the reasons why we at Schmincke do not use linseed oil as the main binder in light or white colours.

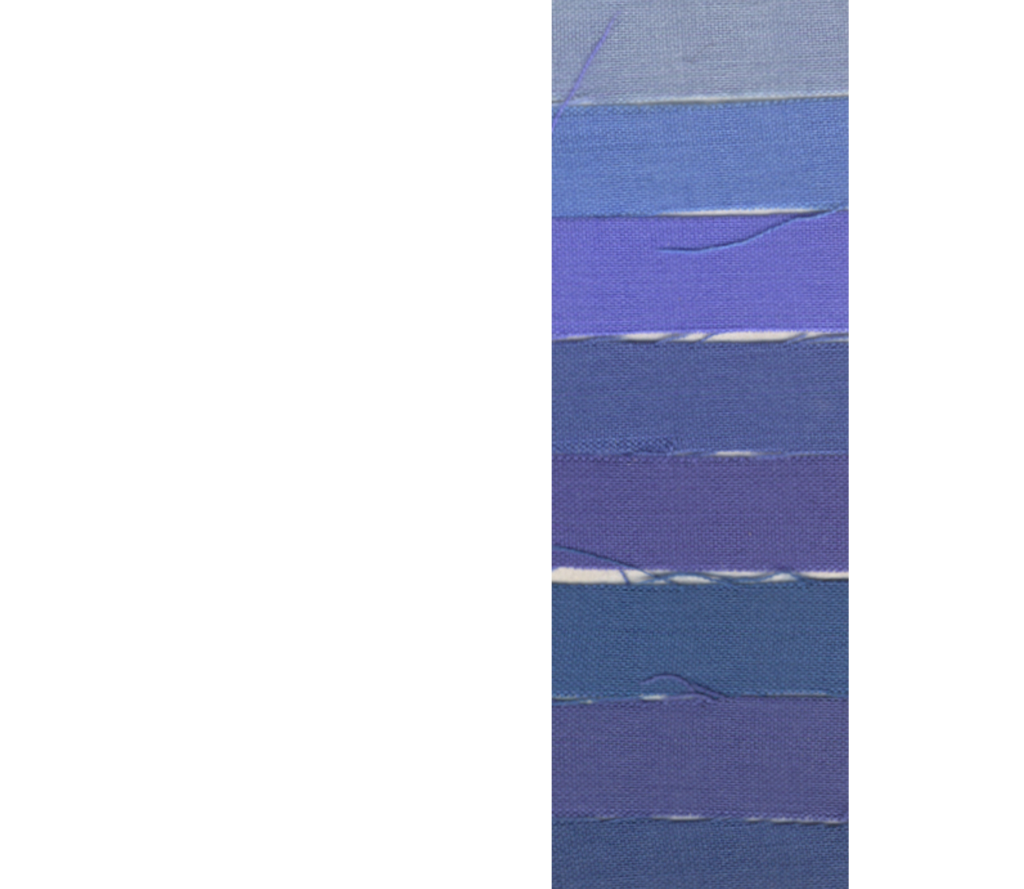

Schmincke designs its tests to reflect the environment in which the colours will be used. For example, each colour type is applied to a standard ground using typical application techniques for that particular colour (for HORADAM® watercolours, this would consist of defined scumbles on artists’ watercolour paper).

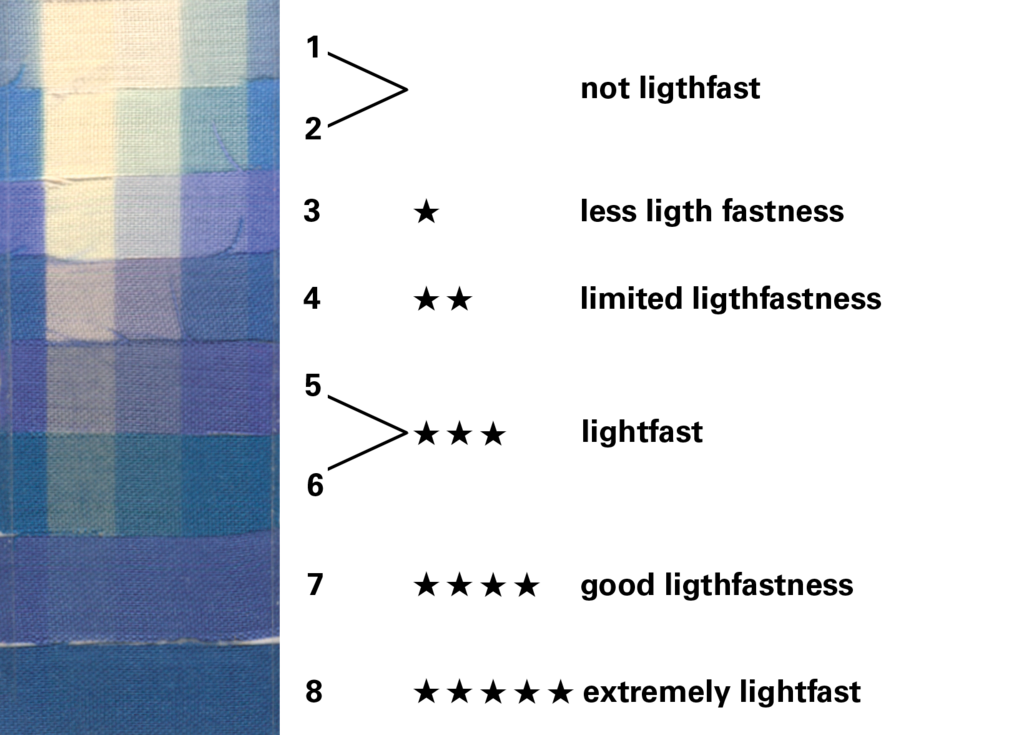

The applied colour is then checked for lightfastness using a special “yardstick”. The yardstick is known as a “blue wool scale” and consists of eight strips of wool fabric, each dyed using a different dye with different lightfastness properties. The samples are placed in a special light-test device, where they are subjected to the light of a xenon lamp (very similar to sunlight). Part of the test strips and the samples are exposed to the light, and part of them is covered to beused as a reference later. This standardised test is run until the most lightfast test strip – Level 8 – has begun to fade slightly. The colour samples are then compared to the test strips and given a lightfastness rating. The rating consists of the level of the blue scale whose change in colour most closely corresponds to the change in the colour samples.

Illustration:

unexposed “blue wool scale” and consists of eight strips of wool fabric, each dyed using a different dye with different lightfastness properties

The Schmincke lightfastness rating system uses an accredited 5 ★ system based on the blue wool scale rating:

Resistance to sunlight is also tested in real-life sunlight conditions: on Schmincke’s rooftop, where colours are tested in a rack at a 45° slope facing south. Unlike the „quick” xenon test, this test can last from 2 to 2,5 years, depending on the actual amount of solar radiation.

We carry out this extensive procedure every time we change the formula – and not just every time we change the pigment – in order to check that our colours still meet our stringent lightfastness standards. Our many years of experience have shown that consistently rating and documenting the lightfastness of our products in brochures and on tube and bottle labels gives users extremely specific, understandable and practical information about the lightfastness of the overall system.

The described product attributes and application examples have been tested in the Schmincke laboratory. The information is based on our current state of technical findings and experience. Due to the diversity of applications in terms of painting techniques, materials and working conditions, as well as numerous possible influences, this information is based on a general application range. A legally binding guarantee of specific attributes or the suitability for a specific usage purpose cannot be derived from our information; therefore the use of the products must be adapted to the users' individual conditions and tested in trials. For this reason, we cannot provide a warranty for product attributes and/or assume liability for damages that occur in connection with the use of our products.

By the way:

Specifics for handling and product safety you will find on our website www.schmincke.de (e.g.download/safety data sheets). For special questions please don´t hesitate to ask our team in the lab! The best way to get in contact with them is via mail at: